AWS Certified Welder Program: Requirements, Cost, And Test

Welding certifications separate skilled professionals from the rest of the pack. Among the most recognized credentials in the trade, the AWS Certified Welder Program stands as the industry standard for proving your abilities under real-world conditions. Unlike paper-based exams, this certification tests what actually matters: your hands-on welding performance evaluated against strict American Welding Society codes.

At bluecollarjobs, we regularly see employers specifically requesting AWS-certified candidates in their job postings. That credential on your resume signals to hiring managers that you’ve passed rigorous performance testing and can deliver quality welds that meet code requirements. For welders looking to command higher pay and access better opportunities, understanding this certification process is a practical first step.

This guide breaks down everything you need to know about the AWS Certified Welder Program, from eligibility requirements and the testing process to costs and career benefits. Whether you’re a newer welder considering certification or an experienced professional looking to formalize your skills, you’ll find the specifics you need to make an informed decision and prepare for success.

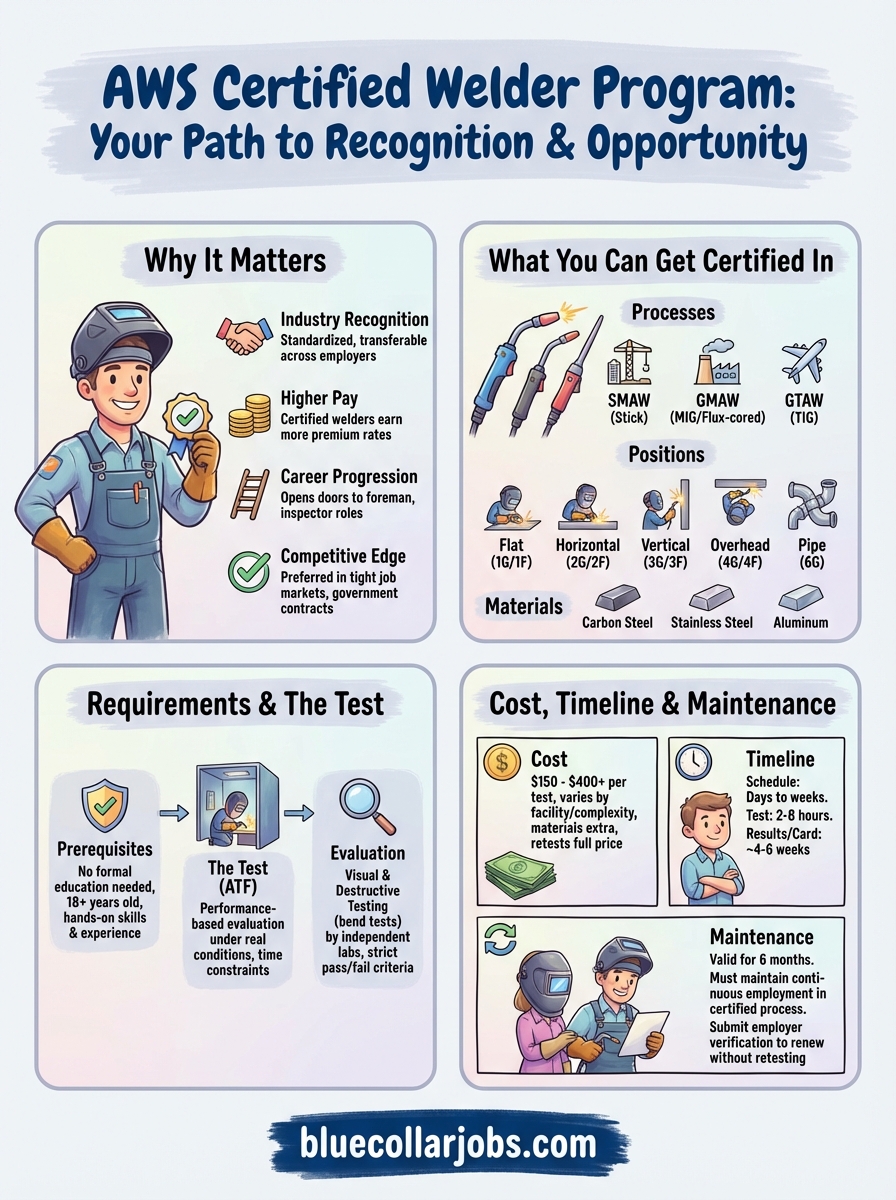

Why the AWS Certified Welder program matters

The aws certified welder program carries weight in hiring decisions across the country. When employers post welding positions, they regularly specify AWS certification as a preferred or required qualification because it gives them confidence in your ability to produce code-compliant welds without extensive on-the-job testing. This certification removes guesswork from the hiring process and proves you can perform under the pressure of formal evaluation.

Industry recognition that opens doors

Employers trust AWS certification because it represents standardized testing administered by independent facilities following strict protocols. Unlike internal company certifications that only matter at one workplace, your AWS credential transfers across employers, states, and industries. Construction firms, pipeline companies, shipyards, and manufacturing plants all recognize the same AWS standards, which means your certification holds value whether you’re welding structural steel in Texas or working on oil rigs in Louisiana.

Your AWS Certified Welder status also meets the requirements for many government contracts and regulated industries that mandate certified welders for specific projects. Without this credential, you simply cannot bid on or work certain jobs, no matter how skilled you might be. Union shops and large contractors often require AWS certification before they’ll even consider your application, making it a practical prerequisite rather than just a nice addition to your resume.

Pay advantages and career progression

Certified welders consistently earn higher hourly rates than their non-certified counterparts doing similar work. The specific premium varies by region and specialization, but employers pay more for the assurance that comes with verified skills and code knowledge. When you hold AWS certification, you position yourself for the better-paying positions that companies reserve for welders they can trust on critical projects.

AWS certification proves you’ve passed performance testing under supervision, which gives employers confidence to assign you to higher-responsibility work without costly trial periods or rework.

Career advancement becomes more accessible with AWS credentials on your resume. Foreman positions, quality control roles, and welding inspection jobs often require or strongly prefer candidates who hold active AWS certification. Companies promote certified welders to supervisory positions more readily because the certification demonstrates both technical competence and a commitment to professional standards. Your path from journeyman to lead welder or supervisor shortens significantly when you can point to this recognized credential.

Competitive edge in tight job markets

During economic downturns or when competition for positions intensifies, AWS certification separates you from the crowd of applicants. Hiring managers sorting through stacks of resumes or online applications use certification status as a primary screening criterion to quickly identify qualified candidates. Two welders with similar experience levels rarely get equal consideration when one holds AWS certification and the other doesn’t.

Your certification also provides leverage during salary negotiations and contract discussions. When you can document your abilities through an independently verified credential, you negotiate from a position of strength rather than asking employers to take your word about your skills. This concrete proof of competency helps you command the compensation your abilities deserve and makes it harder for employers to justify lower pay rates.

Project-based work and traveling welding positions become more accessible with AWS credentials. Many short-term contracts and specialty jobs require welders who can start immediately without spending days or weeks proving themselves through company-specific qualification tests. Your AWS certification serves as pre-approval that lets you hit the ground running on new projects, making you a more attractive candidate for the flexible, often higher-paying project work that keeps experienced welders employed year-round.

What you can get certified in

The aws certified welder program lets you pursue certification in specific welding processes, positions, and material combinations rather than offering a single generic credential. You select the exact certification that matches your current skills or the job requirements you’re targeting, which means your credential precisely demonstrates what you can actually weld. This specificity helps employers understand your exact capabilities without ambiguity.

Welding processes covered

AWS offers certification across multiple welding methods that you’ll encounter in professional settings. The Shielded Metal Arc Welding (SMAW) certification, commonly called stick welding, remains the most widely pursued credential because of its prevalence in construction and maintenance work. You can also certify in Gas Metal Arc Welding (GMAW), which includes both MIG welding and flux-cored processes that dominate manufacturing and fabrication shops.

Gas Tungsten Arc Welding (GTAW), known as TIG welding, represents another major certification category that aerospace, nuclear, and precision industries require. Submerged Arc Welding (SAW) certifications matter for shipbuilding and heavy equipment manufacturing where you’re welding thick plates. Your choice of process depends on where you work or want to work, since different industries prioritize different welding methods based on their specific production needs and code requirements.

Position and joint configurations

Your certification specifies the welding positions you tested in, which directly affects what jobs you qualify for. Flat position (1G or 1F) certifications are the easiest to obtain but limit you to work on flat surfaces. Horizontal (2G or 2F), vertical (3G or 3F), and overhead (4G or 4F) positions each require separate testing and expand your employment options considerably.

Getting certified in multiple positions, especially vertical and overhead, qualifies you for higher-paying positions that many welders cannot fill.

Pipe welding certifications follow different position designations (2G, 5G, 6G) and carry premium value in pipeline, petrochemical, and plumbing work. The 6G position certification, which requires welding a pipe at a 45-degree angle in all positions, represents the highest difficulty level and commands the best pay rates across the industry.

Material specifications

AWS certifications specify the base metal type and thickness range you qualified on during testing. Carbon steel represents the most common material for certification, but you can also certify in stainless steel, aluminum, and other alloys depending on industry needs. Thicker materials generally require more skill and open doors to structural and pressure vessel work that pays premium rates.

Your material specification matters because it determines what you’re legally qualified to weld under code. Certifying on thicker material qualifies you to weld thinner material in the same process and position, but not vice versa. This principle of qualification by range means strategic certification choices expand your work opportunities more efficiently than randomly selecting test parameters.

Requirements and eligibility

The aws certified welder program sets specific baseline requirements you must meet before attempting certification testing. Unlike some credentials that let anyone register and pay fees, AWS certification demands you demonstrate actual welding ability rather than just theoretical knowledge. Understanding these requirements upfront saves you time and money by ensuring you’re ready before scheduling your test at an authorized facility.

Basic qualifications to apply

You need no formal education credentials or high school diploma to pursue AWS certification, which makes it accessible to self-taught welders and those who learned through apprenticeships or on-the-job training. The program focuses entirely on your hands-on performance rather than academic background, meaning your ability to produce quality welds matters more than where or how you learned. This practical focus reflects the reality of welding work, where employers care about results rather than classroom hours.

Most testing facilities require you to be at least 18 years old to sit for certification exams, though some accept candidates as young as 16 with parental consent. You’ll need to provide valid government-issued photo identification when you arrive for testing, so bring your driver’s license, state ID, or passport. Testing facilities strictly verify identity to prevent credential fraud and maintain the program’s integrity across the industry.

Physical and skill prerequisites

Before you schedule testing, you must demonstrate sufficient welding experience in your chosen process and position to an AWS Accredited Testing Facility. This doesn’t mean formal documentation or logged hours, but you need to convince the testing coordinator that you can realistically pass the performance exam rather than waste everyone’s time and your money. Most facilities want to see you actually weld before they’ll schedule your certification test.

Your ability to consistently produce acceptable welds in practice directly determines whether you’re ready for certification testing, not how many months you’ve been welding.

Physical requirements include the ability to maintain welding positions for extended periods, handle equipment safely, and work in various orientations including overhead and vertical positions. You must have adequate vision (corrected or uncorrected) to see the weld pool clearly and sufficient hand-eye coordination to control the arc. Hearing protection and respiratory fitness matter since welding environments involve noise exposure and fume generation that you’ll encounter during testing.

Your baseline skill level should include consistent arc starts, proper travel speed control, and the ability to maintain correct electrode angles throughout the weld. Testing facilities expect you to bring your own welding equipment or rent theirs, so equipment familiarity matters before you show up. Coming prepared with these foundational skills maximizes your chances of passing on the first attempt and avoiding retesting fees.

How the test works at an AWS ATF

The aws certified welder program requires you to pass performance-based testing at an AWS Accredited Testing Facility (ATF) rather than completing online modules or written exams. These facilities operate independently from AWS and maintain standardized testing conditions that ensure fair evaluation across all candidates. You’ll find ATFs at community colleges, welding schools, and commercial testing centers throughout the country, with locations searchable through the AWS website.

What happens during your test session

Your test day begins with identity verification and a review of the specific certification you’re pursuing, including process, position, material, and thickness parameters. The testing coordinator assigns you a workstation with the required base metal and provides access to welding equipment, though many facilities require you to bring your own gear to ensure you’re working with familiar tools. You receive the joint configuration specifications and any preparation requirements before striking your first arc.

Testing conditions mirror real production environments rather than idealized practice scenarios. You work under time constraints appropriate to the process and position, typically ranging from 30 minutes to several hours depending on the complexity of your certification. The testing proctor observes your work throughout the session to verify you’re following proper safety protocols and not receiving outside assistance, but they don’t provide coaching or technical guidance during the actual welding.

Evaluation criteria and acceptance standards

After you complete your test welds, the facility sends your completed assemblies to an independent inspection lab that evaluates them against AWS code requirements. Inspectors use both visual examination and destructive testing methods like bend tests to verify your welds meet acceptance criteria. Your welds must show proper penetration, acceptable porosity levels, correct bead profiles, and pass mechanical testing without cracking or separation.

Visual inspection catches surface defects like undercut and excessive reinforcement, while bend testing reveals internal flaws that compromise weld integrity under stress.

The inspection process follows strict pass/fail criteria outlined in AWS D1.1 or other applicable codes depending on your certification type. You either meet all requirements and receive certification, or you fail and must retest. Partial credit doesn’t exist in AWS certification, which maintains the credential’s value by ensuring every certified welder demonstrates consistent competency across all evaluation parameters.

Getting your results and documentation

Results typically arrive within two to four weeks after your test date, though timing varies based on inspection lab schedules and facility processing speeds. Passing candidates receive an official AWS certification card and wallet card that specify your exact qualifications including process, position, material, and code. Your certification information enters the AWS online database where employers can verify your credentials using your unique certification number.

Cost, timeline, and keeping it active

Pursuing certification through the aws certified welder program requires financial investment and time commitment that varies based on your chosen process, position, and testing location. Understanding these costs upfront helps you budget appropriately and avoid surprises when you’re ready to test. Most welders find the return on investment comes quickly through higher wages and better job opportunities that certified status provides.

Testing and certification fees

The actual certification test costs between $150 and $400 depending on the specific process, position, and material thickness you’re testing on. More complex certifications like 6G pipe welding in stainless steel cost more than flat position carbon steel tests because they require additional materials and inspection time. Your testing facility sets these prices, so rates vary by location and facility type, with commercial testing centers typically charging more than community colleges or trade schools.

Beyond the base testing fee, you’ll pay for material costs if the facility doesn’t include them in the quoted price, which can add $50 to $150 to your total. Retesting after a failed attempt requires paying full fees again, making solid preparation before your first attempt a financially smart decision. Some facilities offer package deals for multiple certifications tested during the same session, which reduces your per-certification cost if you’re pursuing several credentials simultaneously.

Timeline from start to finish

Scheduling your test takes anywhere from a few days to several weeks depending on facility availability and your specific certification requirements. Busy testing centers may have limited slots, especially during peak hiring seasons when many welders pursue certification. The actual test session consumes two to eight hours including setup, welding time, and cleanup depending on your certification complexity.

Plan for four to six weeks from test date to receiving your official certification card, though some facilities process results faster during slower periods.

Results processing and certification issuance typically require three to four weeks after your test date while inspectors evaluate your welds and AWS processes your documentation. Rush processing isn’t available, so factor this timeline into your job search or contract start dates that require verified certification status.

Keeping your certification current

AWS certifications remain valid for six months from your test date unless you maintain continuous employment requiring the specific welding you’re certified in. Your employer must provide written documentation of your ongoing work every six months to extend your certification without retesting. Without this employment verification, your certification expires and you must retest completely rather than simply renewing through paperwork.

Tracking your certification status through the AWS online database helps you avoid letting credentials lapse unexpectedly. Set reminders for your six-month renewal deadlines and communicate with your employer about documentation needs well before expiration dates approach.

Next steps

The aws certified welder program provides you with industry-recognized credentials that expand your career options and increase your earning potential across the United States. You now understand the testing process, costs, and requirements needed to pursue certification in your specific welding discipline. Your preparation should focus on consistent practice in your chosen process and position, followed by scheduling your test at a nearby AWS Accredited Testing Facility when your confidence in your abilities reaches the point where passing becomes realistic rather than hopeful.

Finding employers who value certified welders becomes easier when you know where to look. Our blue collar careers blog features current job opportunities and industry insights that help you understand which certifications matter most in your region. Your investment in certification pays returns through better job offers and the confidence that comes from verified professional skills that employers can trust without additional testing.

Want blue collar jobs delivered to your inbox?

Want blue collar jobs delivered to your inbox?